The Complete Guide to Latch Types

What is a Latch?

Ordinary users encounter latches daily, from magnetic handles on kitchen cabinet doors to latches releasing car trunks. In short, a latch is a fastening device that connects two surfaces while allowing or restricting access to an enclosure’s interior.

Types of Latches

Latches vary widely in complexity depending on their application. Engineers should carefully consider the following types when evaluating their design needs:

Cam Latches

Cam latches are simple and cost-effective. They consist of a body (typically mounted on a moving panel or door) and a cam lever that rotates to engage a fixed panel. When the door closes, the cam rotates behind the fixed panel to secure the door. The lever can be actuated manually or with tools. Some include locking mechanisms for added security. Common in cabinets and enclosures, cam latches are made from materials like stainless steel or zinc.

Similar to cam latches, compression latches use a rotating cam lever but apply clamping force between two surfaces. This force minimizes vibration, noise, or compresses gaskets to seal against dust and moisture, protecting equipment and reducing maintenance. They offer adjustable compression for diverse applications.

Push-to-Close/Spring Latches

Also called "latch bolts," these secure doors or panels simply by pushing them shut. A spring-loaded cam snaps into place behind a strike plate or hook, automatically locking without handles. They’re durable, ideal for industrial, construction, or transportation equipment, and can include key locks. Materials range from plastics to stainless steel, with mounting options like surface, flush, or adhesive. Examples include commercial walk-in refrigerators and vehicle doors.

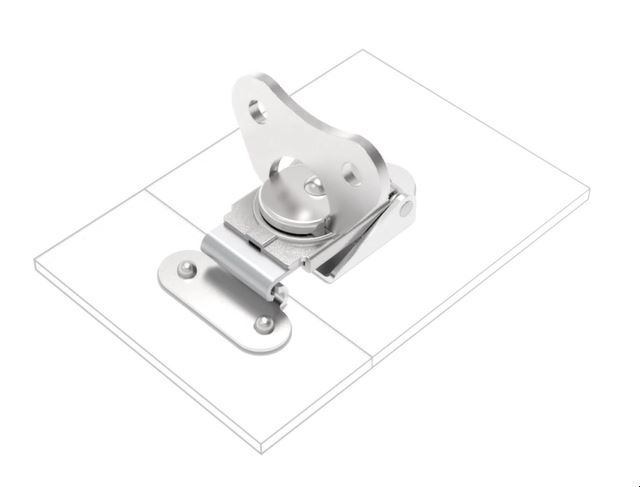

Draw Latches

Draw latches use tension to pull two surfaces together within the same plane. Comprising an operating mechanism and a fixed catch, they reduce vibration and are often exposed on engine covers or HVAC units. Their simplicity makes them economical for basic applications.

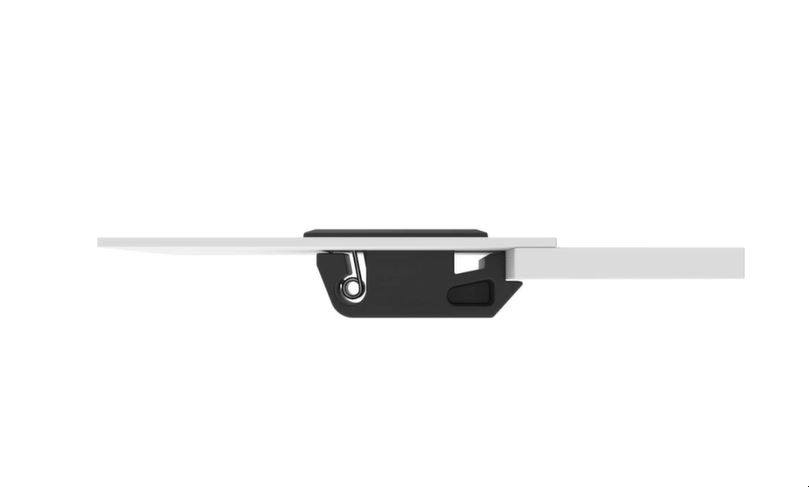

Slide Latches

These use a sliding or rotating component to secure surfaces behind a fixed part. Manual operation and anti-vibration designs are common, with material choices based on load and environmental needs.

Choosing the Right Latch

Selecting a latch requires evaluating factors like size, weight, force, and environment (indoor vs. outdoor):

Indoor Latches

Indoor applications typically have lower demands. Cost-effective materials like plastic or zinc suffice, and non-locking options may work if security is not critical.

Outdoor Latches

Outdoor use requires corrosion-resistant materials (e.g., stainless steel) and compliance with standards like IP, NEMA, or UL for weatherproofing. Enhanced security features, such as complex locks, deter tampering or vandalism.

Mechanical vs. Magnetic

Latches can be mechanical or magnetic. Some incorporate electronic features for hands-free operation.

Visible vs. Hidden

Visible latches suit applications requiring user visibility, while hidden versions offer sleek aesthetics or added security (e.g., hidden refrigerator latches).

Custom Latches

For specialized needs, engineers should collaborate with suppliers to develop custom solutions. High-quality latches enhance user experience—for example, a smooth-glovebox latch can elevate a vehicle’s perceived quality.

For more information or to discuss custom latch solutions, contact jufu. Our team is ready to help you select the ideal latch for your application.

Link to this article:https://www.topseeklocks.com/TechnicalArticles/692.html

English Official Website:http://www.topseeklocks.com

Dongguan Jufu Metal Products Co., Ltd. is a production enterprise integrating the development and design of caravan door locks, caravan furniture locks, caravan handles, caravan toolbox locks, caravan bathroom door locks, caravan accessories, mould manufacturing, zinc alloy die-casting manufacturing and processing, assembly line assembly, choose us! Choose success!

Unlocking a new security exper

Unlocking a new security exper

what are captive screws?

what are captive screws?

rv lock buying guide: high-fre

rv lock buying guide: high-fre

what are quick-access fasten

what are quick-access fasten