Fastener Type: Complete Guide

Engineers often overlook the selection of fasteners when designing products, even though fasteners are crucial components in product design. Without proper knowledge, engineers may struggle to find the right fasteners for their specific application. With a wide variety of options available in the market, it can be overwhelming. Engineers must consider various factors such as material, environmental conditions, and the specific needs of the product when selecting fasteners.

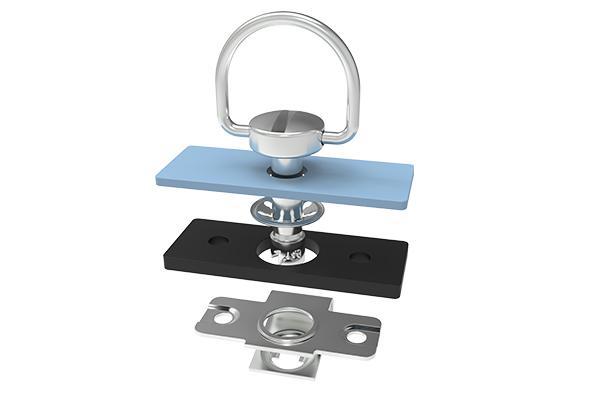

What are Fasteners?

Fasteners are hardware devices used to mechanically connect or secure multiple objects together. They create removable, non-permanent joints. A fastener system may include bolts, screws, studs, nuts, fasteners, or other components. Fasteners enhance product performance in various ways, such as providing access points for equipment maintenance. Without such fasteners, users may find it difficult to access the interior of devices.

Types of Fasteners

There are many types of fasteners available for engineers to choose from, including bolts, screws, nuts, washers, rivets, and studs. Below are a few examples commonly used by Topseek:

Screws:

Screws engage with pre-formed internal threads. While standard screws may easily loosen during operation, Topseek's anti-loosening screws use a spring-loaded, self-aligning floating design, ensuring secure panel connections and preventing loss even when loosened.

DZUS® Quarter-Turn Fasteners:

These fasteners allow for quick assembly and disassembly with a 90-degree rotation, offering stable clamping force and superior vibration resistance.

Quick-Release Fasteners:

Designed for quick installation and removal, these fasteners ensure uniform clamping force, reduce installation costs, and enhance maintenance efficiency.

Rivets:

Rivets form a permanent joint with a smooth surface finish. Topseek's anti-tamper design rivets (resistant to drilling and penetration) can be installed without special tools and come in corrosion-resistant materials like aluminum and stainless steel.

LOCKWELL Quick-Release Pins:

These pins feature a button for one-handed locking/releasing, with a spring-driven internal shaft that automatically resets after releasing the button to ensure tight connection.

How to Choose the Right Fastener?

Key Principles:

Size: The size must meet the aesthetic and strength requirements of the application. Incorrect sizing can lead to operational failures.

Installation Methods: Options include self-locking threaded nuts, snap-in sockets, etc. Bolts, studs, and screws can connect with panels via fasteners.

Other Design Considerations:

Material: Choose materials based on the application. For example:

Steel/Stainless Steel: For medium to high-load scenarios (e.g., automotive maintenance panels that must withstand vibrations).

Thermoplastic: For low-load applications.

Lifespan: Estimate the fastener's service life (number of installation/removal cycles), considering factors like temperature, corrosion, etc. For instance, fasteners in automotive maintenance panels should match the vehicle's maintenance cycle.

Environmental Conditions: Evaluate exposure to vibrations, impacts, temperature, humidity, chemicals, and UV rays. For example, fasteners used outdoors should be weather-resistant, while automotive fasteners must be vibration-resistant.

Safety Requirements:

Low-security: Winged, circular, or knob-type manual fasteners.

High-security: Fasteners that require special tools (e.g., cross or slotted screws) or tamper-resistant designs (e.g., hex sockets with center pins).

If off-the-shelf fasteners do not meet specific needs, Topseek experts can provide customized solutions.

For more information or technical consultations, feel free to contact Topseek.

Link to this article:https://www.topseeklocks.com/TechnicalArticles/Fastener-Type--Complete-Guide.html

English Official Website:http://www.topseeklocks.com

Dongguan Jufu Metal Products Co., Ltd. is a production enterprise integrating the development and design of caravan door locks, caravan furniture locks, caravan handles, caravan toolbox locks, caravan bathroom door locks, caravan accessories, mould manufacturing, zinc alloy die-casting manufacturing and processing, assembly line assembly, choose us! Choose success!

Unlocking a new security exper

Unlocking a new security exper

what are captive screws?

what are captive screws?

rv lock buying guide: high-fre

rv lock buying guide: high-fre

what are quick-access fasten

what are quick-access fasten