Topseeklock:Compression latch working principle and technical analysis

in the modern security landscape, door lock technology has evolved from simple mechanical structures to sophisticated intelligent systems. among these advancements, the compressive door lock stands out as an innovative mechanical locking device. its unique structural design and enhanced security features have made it a preferred choice for both residential and commercial applications. this article delves into the working principles, key components, and practical applications of this technology, highlighting the technical advantages of the topseeklock compressive door lock.

i. core design concept of compressive door locks

traditional door locks typically utilize a linear retractable bolt mechanism, operated by a spring to facilitate locking and unlocking. in contrast, compressive door locks introduce a three-dimensional compression structure. this design establishes a dynamic compressive relationship between the bolt and the lock body through a multi-stage linkage system. such an arrangement not only enhances resistance to external force attacks but also dissipates impact energy through compressive deformation, significantly elevating the lock's physical security standards.

ii. key components and operational workflow

1. specialized bolt system

the compressive door lock features a segmented bolt design, comprising a primary bolt made of hard alloy and a secondary bolt crafted from elastic composite materials. the primary bolt bears the door's pressure, while the secondary bolt is equipped with built-in sensors to monitor pressure variations in real-time. upon detecting an external impact on the door, the secondary bolt absorbs the shock through compressive deformation and transmits the energy to the internal buffer layer of the lock body via mechanical transmission.

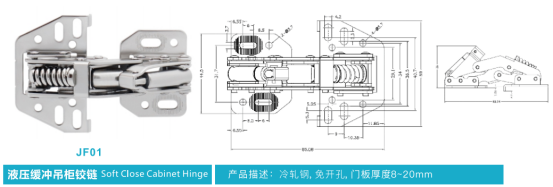

2. gear compression transmission module

inside the lock cylinder, a high-precision planetary gear set is installed. when a key is inserted, it engages a three-stage gear system:

first stage: controls the extension and retraction of the bolt.

second stage: activates the lock body's compression mechanism.

third stage: engages the anti-tamper alarm system.

these gears are designed with differential configurations to ensure precise and coordinated movements.

3. dynamic pressure balancing system

the lock body incorporates hydraulic dampers and an array of springs. when the bolt is subjected to external pressure, hydraulic fluid is channeled through micro pathways into various chambers. this, combined with the spring's rebound action, establishes a dynamic pressure equilibrium. this system can withstand vertical impacts exceeding 2000n, far surpassing the standard 500n threshold of conventional anti-theft locks.

iii. detailed operational phases

1. locking phase

rotating the key clockwise by 120° engages the gear set, fully extending the primary bolt. at this point, the secondary bolt enters a pre-compressed state, and the hydraulic damper completes energy storage. the internal compression plates of the lock body retract along guide rails towards the center, forming a tightly sealed "compression box" structure.

2. anti-tamper mode

if tampering tools are inserted, the anti-drill plate within the lock cylinder immediately immobilizes the keyway. should forced entry cause the secondary bolt's pressure to exceed a set threshold, the compression mechanism triggers a linkage system, locking the primary bolt in place and activating a 105-decibel alarm.

3. unlocking process

turning the key counterclockwise reverses the gear movement, releasing the pressure from the compression plates and allowing hydraulic fluid to return to its initial chambers. as both bolts retract synchronously, pressure sensors continuously monitor the retraction resistance. if abnormal resistance is detected (indicative of lock-picking attempts), the system automatically locks and sends a wireless alert.

iv. technical advantages of the topseeklock compressive door lock

as a flagship product in this domain, the topseeklock compressive door lock offers several innovative features:

military-grade protection: constructed with a titanium alloy body and tungsten carbide bolt, it has achieved ul-437 security certification, capable of withstanding continuous cutting by an angle grinder for up to 15 minutes.

intelligent pressure adaptation: equipped with an ai chip that learns user habits, it automatically adjusts the compression mechanism's resistance, prolonging the lock's lifespan.

frictionless transmission: incorporating graphene coatings within the gear set reduces mechanical wear by 83%, ensuring maintenance-free operation for a decade.

environmental adaptability: fitted with temperature and humidity sensors, it maintains a stable compression ratio in extreme conditions ranging from -30°c to 70°c.

conclusion

through mechanical innovation, compressive door locks have redefined physical security standards. the topseeklock brand elevates this technology further, offering a unique dynamic compression mechanism that effectively counters forced entry while seamlessly integrating intelligent design for optimal security and convenience. for users seeking unparalleled protection, the topseeklock compressive door lock serves as an evolving intelligent barrier, fortifying building security.

Reprinted with permission from:https://www.topseeklocks.com/ Link to this article:https://www.topseeklocks.com/news/576.html

English Official Website:http://www.topseeklocks.com

Dongguan Jufu Metal Products Co., Ltd. is a production enterprise integrating the development and design of caravan door locks, caravan furniture locks, caravan handles, caravan toolbox locks, caravan bathroom door locks, caravan accessories, mould manufacturing, zinc alloy die-casting manufacturing and processing, assembly line assembly, choose us! Choose success!

Strengthening Partnerships: Fa

Strengthening Partnerships: Fa

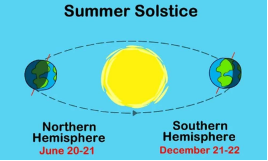

The summer solstice has arrive

The summer solstice has arrive