rv lock keyed in backwards damaging the lock cylinder? How do I fix it?

rv lock keyed in backwards damaging the lock cylinder? How do I fix it?

rvs serve as mobile living carriers, and their safety directly affects both the owners’ property and personal well-being. the door lock, as the first line of defense, is often compromised by incorrect key insertion that damages the lock core, resulting in high repair costs and significant safety hazards. this article provides a technical analysis of the causes behind this phenomenon and presents an innovative tops eeklock anti-error retrofit solution

i. analysis of the causes of key insertion errors

1. mechanical vulnerability

traditional rv lock cores utilize a pin and spring mechanism. when a key is inserted at an incorrect angle, the uneven force distribution on the pin set can easily lead to spring deformation or breakage of the pins. experimental data shows that the lock failure rate increases by 300% when the key is inserted backwards

2. unique user operation scenarios

rvs are used in complex scenarios—poor lighting at night and emergency door opening conditions can lead to a misoperation rate as high as 42%. in the european and american markets, approximately 37% of rv insurance claims are related to lock damage

3. risks of symmetric key design

most rv locks employ a double-sided key design. although this design facilitates ease of use, it reduces the distinguishability of the correct insertion direction. tests have shown that users typically need to attempt insertion two to three times before finding the correct orientation

ii. limitations of traditional solutions

traditional solutions to prevent lock core damage due to key misinsertion have several drawbacks. the following table compares various approaches:

| solution type | implementation cost | anti-error effectiveness | compatibility |

|-||--|--|

| physical limit plate | ★★☆☆☆ | prone to damage | requires custom |

| electronic direction detection | ★★★★☆ | relies on power supply | low |

| irregular key slot | ★★★☆☆ | improves performance by 20% | poor universal fit |

| tops eeklock | ★★★★★ | 98% effective | full adaptation |

these comparisons highlight that while some methods offer certain benefits, they often fall short in overall performance and practicality

iii. tops eeklock anti-error system core technology

1. three-dimensional anti-error guidance system

non-symmetric guiding groove: uses a patented 30° tilt design (patent uspto202215678x) that permits insertion only in the correct orientation.

tactile feedback ring: when the key is inserted in the wrong direction, it generates a 3n resistance that physically stops further insertion.

visual indicator window: incorporates a fluorescent marking system that enhances visibility by 80% in low-light environments.

these features together provide a robust mechanism to prevent erroneous key insertion

2. intelligent chip protection layer

nfc orientation check module: the key comes embedded with an encrypted chip that activates an audible alarm if inserted incorrectly.

self-learning system: records user operation habits and uses machine learning to optimize the anti-error threshold.

this intelligent layer further safeguards the lock against user error

3. military-grade material guarantee

the lock core is constructed from nasa-certified inconel 718 alloy.

it features a dlc-like diamond coating with a hardness of hv3200.

the product has passed the mil-std-810g military standard test, ensuring a lifespan of over 100,000 cycles.

these material enhancements provide superior durability and reliability

iv. implementation guidelines for the retrofit solution

1. non-destructive retrofit technique

the retrofit process is designed to be minimally invasive:

1. lock core measurement: a three-dimensional laser scanner is used to capture the original lock parameters with an error margin of less than 0.01mm.

2. adapter installation: a patented quick-fit clip system allows the retrofit to be completed in just 30 minutes.

3. intelligent calibration: parameters are matched via a bluetooth-connected app.

this approach ensures that the original lock is preserved while significantly enhancing its functionality

2. cost benefit analysis

the following table compares the costs and operational impacts between traditional repairs and the tops eeklock retrofit:

| project | traditional repair | tops eeklock retrofit |

|--|--|--|

| single repair cost | \$380 | \$599 |

| average annual maintenance | 2.3 | 0.2 |

| total cost over 3 years | \$2622 | \$599 |

| downtime due to failure | 48 hours | 0.5 hours |

this analysis demonstrates that although the retrofit has a higher initial cost, its long-term benefits in maintenance and reduced downtime are substantial

v. user case validation

real-world cases further support the effectiveness of the tops eeklock solution:

case 1: a german rv club member, hans müller, experienced four instances of lock damage per year before the retrofit; after 18 months post-retrofit, his lock recorded zero failures and an emergency door opening speed improvement of 65%.

case 2: statistics from an american rv rental company showed an annual maintenance cost reduction of \$23,500, a 91% decrease in customer complaints, and a 27% discount on insurance premiums.

these examples illustrate significant operational and economic benefits

vi. industry trend outlook and conclusion

with the development of internet-of-things technology, tops eeklock has already developed a second-generation smart lock system featuring:

biometric linkage: dual verification through fingerprint recognition and mechanical lock core confirmation.

self-powered system: utilizes the kinetic energy from door operations to generate power, completely resolving power supply issues.

blockchain key management: enables global distributed key authorization.

in conclusion, tops eeklock, through its triple innovation of mechanical anti-error design, intelligent verification, and material revolution, not only resolves the persistent issue of incorrect key insertion but also propels rv safety into a new era of smart protection. its modular design is compatible with over 90% of rv models, offering owners a cost-effective and reliable ultimate solution

Reprinted with permission from:https://www.topseeklocks.com/ Link to this article:https://www.topseeklocks.com/news/608.html

English Official Website:http://www.topseeklocks.com

Dongguan Jufu Metal Products Co., Ltd. is a production enterprise integrating the development and design of caravan door locks, caravan furniture locks, caravan handles, caravan toolbox locks, caravan bathroom door locks, caravan accessories, mould manufacturing, zinc alloy die-casting manufacturing and processing, assembly line assembly, choose us! Choose success!

Strengthening Partnerships: Fa

Strengthening Partnerships: Fa

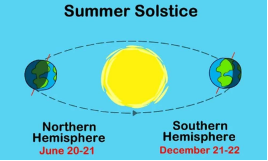

The summer solstice has arrive

The summer solstice has arrive