Compression latch:principle, structure and innovative application

Compression latch: principle, structure and innovative application

"Compression latch" is a locking device that combines the mechanical compression principle and latch mechanism. It is widely used in electrical cabinet doors, car door locks, electronic equipment fixation, and other fields. Its core design goal is to achieve high stability and anti-loosening locking effect through the synergy of compression force and latch structure. This article will analyze the aspects of principle, structural design, application scenarios, and technical advantages.

1. Working principle of compression latch

The core of the compression latch is to drive the claw or steel bolt to complete the locking through the coordination of axial compression force and rotation or translation action. Its working principle can be divided into the following two categories:

1. Mechanical compression type: Pressure is generated by the deformation of springs or compressible components. For example, in cabinet door locks, the spring is compressed when the handle is pressed down, and the driving shaft drives the steel bolt to be stuck in the frame groove to form a locked state.

2. Structural linkage type: The geometric design of the cam surface or positioning piece is used to generate compression force when the shaft rotates or moves. For example, the cam on the shaft surface contacts the housing, triggering the opening or closing of the claws through axial movement, thereby fixing the relative position of the panel and the frame.

2. Typical structure and innovative design

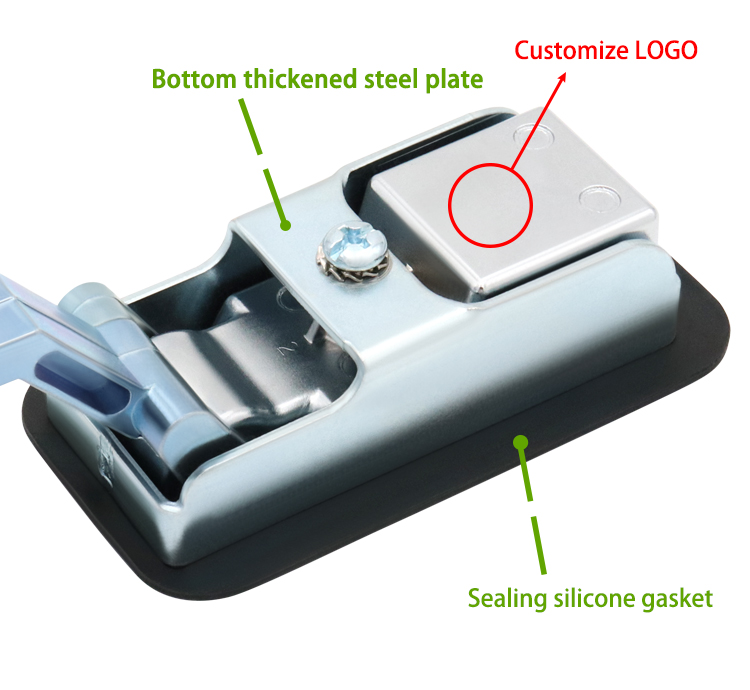

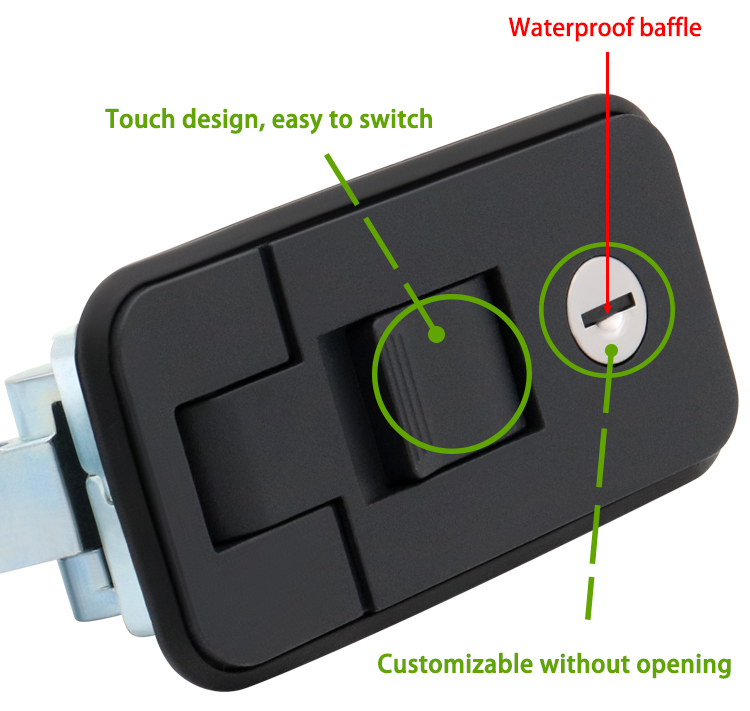

The structural design of the compression latch usually includes the following key components:

1. Base and housing: As the supporting body, the base is usually provided with a handle groove or a guide groove, and the housing has a built-in cam surface or a guide hole to constrain the movement trajectory of the shaft.

2. Shaft and shaft assembly: The shaft can move or rotate in the longitudinal direction, and its surface is designed with a cam or a pin to cooperate with the housing or a positioning member. For example, the hemispherical shaft head of the shaft matches the cavity of the handle connector to ensure the stable transmission of the rotational torque.

3. Compression element: Springs or compressible components (such as conical springs, and foam materials) are the core of achieving compression force. For example, in the car door lock bracket, the compressible component pushes the sliding member to translate after being compressed to achieve the positioning of the window glass or handle.

4. Anti-loosening mechanism: prevent accidental unlocking through double positioning parts, sealing rings or adjustment gaskets. For example, the notches of the first and second positions are matched alternately to ensure that the handle cannot be pressed down when reset to avoid scratches.

3. Application scenarios and technical advantages

1. Industrial electrical cabinet: The compression cabinet door lock drives the spring compression through the handle to drive the steel bolt to lock the cabinet door. Its anti-pry design and high-frequency durability are better than traditional flat locks.

2. Automotive door lock system: The compressible latch bracket is used for the linkage between the window guide rail and the door handle. The sliding part moves horizontally in a compressed state to adapt to the tolerance during door assembly and reduce abnormal noise caused by vibration.

3. Electronic device battery fixation: The combined design of the spring and the positioning part can prevent the battery from falling off due to vibration or impact. For example, the positioning end is disengaged from the card slot by compressing the spring to achieve quick disassembly and assembly.

Technical advantages:

High stability: The dual effects of compression force and mechanical linkage reduce the risk of loosening;

Dustproof and waterproof: The design of the sealing ring and the pressure plate improves environmental adaptability;

Easy installation: The modular structure supports fast assembly, such as fixing the pressure plate or sliding parts by screws.

4. Comparison with electronic latch effect

It is worth noting that the term "latch" in the electronics field specifically refers to the parasitic thyristor effect (Latch-up) in CMOS circuits, that is, the short circuit phenomenon of large current between the power supply and ground triggered by noise. Despite the similar names, the mechanisms of electronic latch and mechanical compression latch are completely different. The former suppresses noise by optimizing the layout design (such as guard ring) or filter capacitor, while the latter relies on the mechanical optimization of the physical structure.

V. Future Development Trends

1. Material Innovation: Use shape memory alloys or high-performance polymers to enhance the durability of compressible components;

2. Intelligent Integration: Embed sensors in mechanical structures to monitor locking status in real time;

3. Lightweight Design: Reduce the weight of metal parts through topological optimization, suitable for new energy vehicles and other fields.

Conclusion

The compression latch achieves efficient and reliable locking function through the clever combination of mechanics and structure. Its design concept is not only reflected in mechanical engineering, but also provides interdisciplinary inspiration for the protection of electronic devices. With the advancement of intelligent manufacturing and materials science, the compression latch will demonstrate its technical potential in more fields.

Reprinted with permission from:https://www.topseeklocks.com/ Link to this article:https://www.topseeklocks.com/news/573.html

English Official Website:http://www.topseeklocks.com

Dongguan Jufu Metal Products Co., Ltd. is a production enterprise integrating the development and design of caravan door locks, caravan furniture locks, caravan handles, caravan toolbox locks, caravan bathroom door locks, caravan accessories, mould manufacturing, zinc alloy die-casting manufacturing and processing, assembly line assembly, choose us! Choose success!

Compression latch:principle, s

Compression latch:principle, s

JUFU locks factory is back!

JUFU locks factory is back!

JUFU's Christmas event

JUFU's Christmas event